Reshaping Industries: Impact of Rotational Molding

When it comes to developing, Rotational Molding is the most reputable approach employed today. It is good for making a wide variety of hollow plastic merchandise in various sizes and shapes for example toys, huge storage units, vehicle elements, and much more. Rotomolding provides for greater layout overall flexibility and also a superior level of durability and strength. This short article will provide an introduction to the art of Rotomolding and the way it can help you design your prosperity.

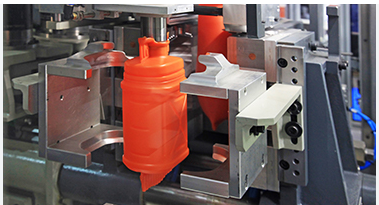

Learning the Rotomolding Process

The Rotomolding process is really a distinctive method which involves warming plastic-type material resins in a oven or mildew and after that slowly spinning the mold along two perpendicular axes. The plastic material melts and jackets the mold’s inner work surface, creating the required form. Right after cooling and solidification, the plastic product is removed from the fungus. The process is inexpensive and may develop big, seamless, and uniformly dense parts, making this product an easy task to keep clean and maintain.

The Benefits of Rotomolding

Rotomolding has a variety of positive aspects over other plastic material production techniques. For beginners, it simplifies the molding method and reduces the requirement for several resources, fixtures, and elements which can be typically required in the injections molding approach. Rotomolding can produce elements which can be more extensive, more firm, capable to endure excessive temperatures and corrosive surroundings. Additionally it is an eco-warm and friendly approach as the plastic materials applied during this process may be re-cycled, recycled or disposed of without damaging environmental surroundings.

Industries That Make use of Rotomolding

Rotomolding is really a functional process that suits numerous market sectors, which includes agriculture, automotive, travelling, medical care, and leisure time. Plastic-type material tanks and containers for fluid storage space, transportation pallets, outdoor and indoor furnishings, and playground products are simply a few examples of items that are manufactured using the Rotomolding process. The cabability to generate numerous products effortlessly implies that Rotomolding can meet the needs of the needs of huge-level developing while time savings and creation expenses.

Important Considerations

In case you are trying to use Rotomolding for item developing, it is important to comply with some key factors for profitable plastic molding. The method depends heavily on accuracy and precision temperatures handle, correct mildew layout, and perfect raw fabric kind. The producer must select great-top quality plastic-type material resources, design the mildew on the appropriate features and look after the ideal temperature in the your oven. These factors are imperative for generating constantly high-quality and reputable products.

Choose a Expert Rotomold Maker

It is recommended to select a competent rotomold maker if you wish to produce substantial-high quality plastic-type material elements persistently. A specialist manufacturer not simply provides the practical experience but also the proper machines and equipment to make certain that the plastic-type goods meet your particular production demands. Constantly select a trustworthy producer using a substantial document in rotational molding, and whose method is accredited and tested for business specifications.

In a nutshell:

Rotomolding is a great choice for shaping your ability to succeed with regards to plastic material developing. It generates seamless and standard thick elements that are really easy to keep at inexpensive costs. Using this type of approach, you can make a selection of substantial-quality plastic merchandise that you can use across various sectors. You want a skilled and experienced company that could focus on your distinct needs while sticking with market criteria. The skill of Rotomolding is really a lifesaver to boosting your generation, supplying overall flexibility, and offering you sturdy and sturdy products that are well worth purchasing.